POLYCOM ASSOCIATES

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to POLYCOM ASSOCIATES

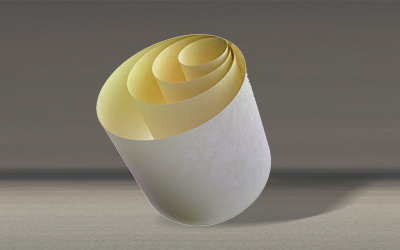

Poly Al

Polycom's POLY AL laminates are composites of co-polymer film coated on either side of aluminium foil. The lamination is done by "Fusion processes"

The 200 MIC Aluminium foil of AA 1100 Alloy having 99% purity & fully annealed is laminated with 50 MIC co-polymer film on either side by fusion Lamination process.

ADVANTAGES

Moisture barrier, resistance to chemical oxidization & corrosion.

Protection against outside interference as a screen.

Sufficient strength with good flexibility.

Non- Magnetic property.

High bond strength.

Polysteel

Polycom's POLYSTEEL laminates are composites of co-polymer film coated on either sides of stainless steel foil. The lamination is achieved by a "Fusion lamination process". The composites manufactured by combining 125mic annealed stainless steel foil with 50mic co-polymer film on either side to cater the armoring needs of fiber optic cable manufacturers.

ADVANTAGES

Annealed flexible stainless steel foil of alloy 304 grade has excellent corrosive resistance & has resistance to chemical & oxidization.

High resistance to abrasion.

Protection to outside interference.

Sufficient radial & compressive strength to cable.

Non-magnetic property.

Ensures cable is rodent & termite proof.

Excellent peel strength.

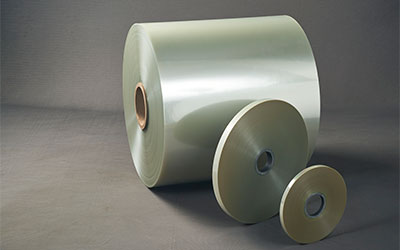

Polyester Tapes

Polycom's Static Discharge Treated (S.T.D.) Grade Clear Polyester Films are specially developed for cable wrap application & are used across many types of cables.

ADVANTAGES:

High Dielectric Strength

High Tensile & Tear Strengths

Good Flexibility

Barrier against migration of Plasticizer

Marking Tapes

Polycom's Marking Tapes Composites are made of specially formulated pigmented systems coated onto a carrier material mostly Polyester Film. The specially formulated pigmented system coating has the property to migrale from the carrier film onto the cable jacket on application of heat & pressure.

ADVANTAGES:

Compatible with PVC / LDPF/ HDFE/ XLPE / NYLON/ Rubber Cable

Requires low temperature for Embossing.

BRIGHT & SHARP EMBOSSING

NO DUST FORMATION ON SUBSTRATE OR ON MACHINE

Polycol

Polycom's Polycol are competitive of Polyester films coloured with special high temperature pigments & are glued together with superior adhesives. The activation of pigments can be customized to produced translucent to opaque versions.

ADVANTAGES:

Good Flexibility

High Tensile / Tear Strength

Pigments are Sandwitched

Foilmylar

Polycom's Foilmylar laminates are composites of Aluminum Foil & Polyester Film. They are glued together with superior adhesives. The Polyester Film provides the mechanical support to the more fragile Aluminum foild which is the active shielding / screening layer of the product.

ADVANTAGES:

Higher Mechanical Strength as compound to Aluminum Foil.

Good Shielding / Screen Properties

Polyprint

Polycom's Plolyprint are Clear Polyester Film, printed with high accuracy machines to contain alpha numeric data such as numbers, company name, cable, product type & many more. The matter can either be surface printed of sandwich in between two films.

ADVANTAGES:

Good Flexibility

A Barrier against Migration of Plasticizer

High Tensile & Tear Resistance

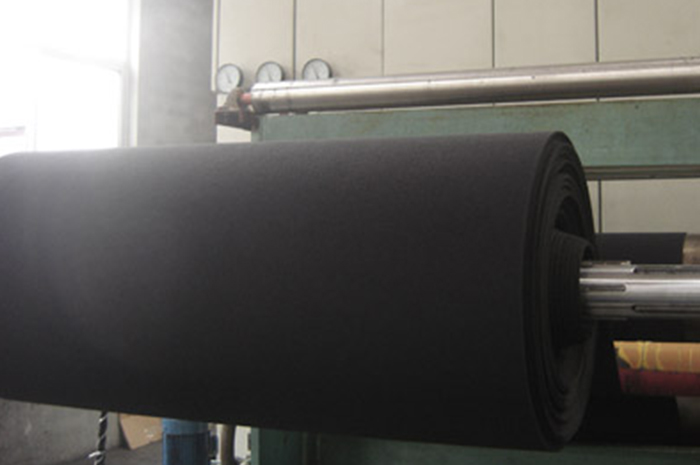

Conductive Non Woven Fleece Cf

Polycom's electrically conductive non-wovens & fabrics are upgraded with binding resin having Conductive property through a high-tech coating process. This meets the growing demands of Motor, power cable & other electrical segments.

ADVANTAGES

High Flexibility.

Helps in controlling over all insulation layers.

Extended services life.

High abrasion resistance during cable production.

Suitable for class 'F'

Low water absorption.

Effective screening for electrostatic charges.

Excellent uniform surface semi conductive properties.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.

Insulation 72473.jpg)